Removing paint and rust from car bodies using laser cleaning technology

When it comes to restoring old cars or preparing them for a fresh coat of paint, one of the biggest challenges is removing old paint and rust from the car body. Traditional methods such as sandblasting or chemical stripping can be time-consuming, messy, and potentially damaging to the metal underneath. However, there is a new technology that is revolutionizing the way we remove paint and rust from car bodies: laser cleaning technology.

What is laser cleaning technology?

Laser cleaning technology uses a high-powered laser beam to remove contaminants such as paint, rust, and other surface coatings from metal surfaces. The laser beam is directed at the surface of the metal, where it vaporizes the contaminants without damaging the underlying metal. This process is known as ablation, and it is incredibly precise and efficient.

Advantages of laser cleaning technology

- Efficiency: Laser cleaning technology is incredibly efficient, allowing for quick and thorough removal of paint and rust from car bodies.

- Precision: The laser beam can be precisely controlled to target specific areas of the car body, ensuring that only the contaminants are removed and the metal underneath remains untouched.

- Environmentally friendly: Unlike traditional methods such as sandblasting, laser cleaning technology does not produce any harmful chemicals or waste, making it an environmentally friendly option.

- Cost-effective: While the initial investment in laser cleaning technology may be higher than traditional methods, the long-term cost savings are significant due to the efficiency and precision of the technology.

How does laser cleaning technology work on car bodies?

When using laser cleaning technology on car bodies, the process is relatively straightforward. The laser beam is directed at the surface of the car body, where it vaporizes the paint or rust. The contaminants are then removed using a vacuum system, leaving behind a clean and bare metal surface ready for further treatment.

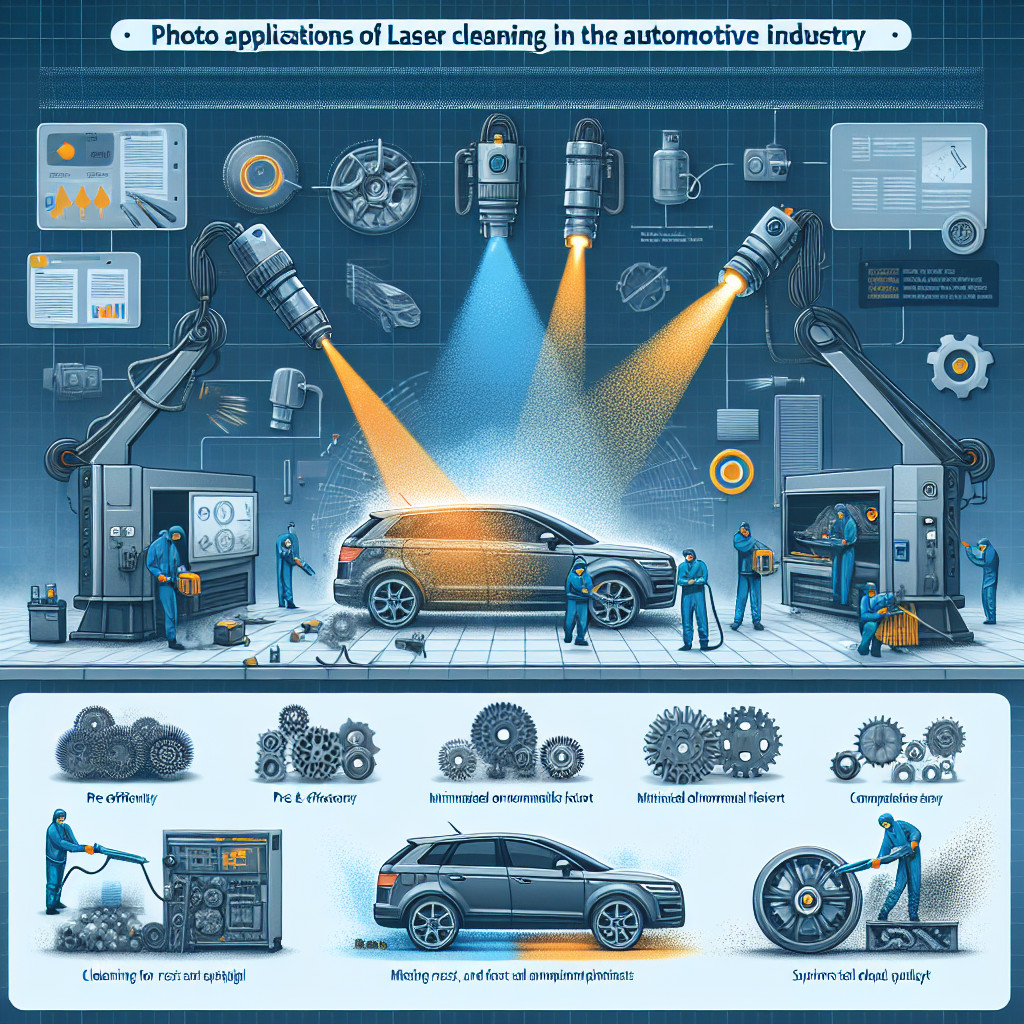

Applications of laser cleaning technology in the automotive industry

Laser cleaning technology is being increasingly used in the automotive industry for a variety of applications, including:

- Restoration of classic cars: Laser cleaning technology is ideal for restoring classic cars by removing old paint and rust without damaging the underlying metal.

- Preparation for painting: Before applying a fresh coat of paint, car bodies need to be free of contaminants. Laser cleaning technology ensures a clean and smooth surface for painting.

- Removal of decals and stickers: Laser cleaning technology can also be used to remove decals and stickers from car bodies without damaging the paint underneath.

Conclusion

Laser cleaning technology is a game-changer when it comes to removing paint and rust from car bodies. Its efficiency, precision, and environmentally friendly nature make it an ideal choice for automotive restoration and painting projects. As the technology continues to advance, we can expect to see even more applications in the automotive industry in the future.

Cleaning engine components with laser technology for improved performance

Engine components play a crucial role in the performance of any vehicle. Over time, these components can accumulate dirt, grime, and other contaminants that can negatively impact their efficiency. Traditional cleaning methods may not always be effective in removing stubborn deposits, leading to decreased performance and potential damage to the engine.

One innovative solution to this problem is the use of laser technology for cleaning engine components. Laser cleaning offers a precise and efficient method for removing contaminants from engine parts, resulting in improved performance and longevity.

How does laser cleaning work?

Laser cleaning works by using a high-energy laser beam to vaporize contaminants on the surface of engine components. The intense heat generated by the laser beam breaks down the contaminants into gas, which is then easily removed from the surface. This process is highly effective in removing even the toughest deposits without causing damage to the underlying material.

Unlike traditional cleaning methods, laser cleaning does not require the use of harsh chemicals or abrasive materials. This makes it a more environmentally friendly and cost-effective solution for cleaning engine components.

The benefits of laser cleaning for engine components

- Improved performance: By removing contaminants from engine components, laser cleaning can help improve the overall performance of the engine. Clean components operate more efficiently, leading to better fuel economy and increased power output.

- Extended lifespan: Regular cleaning with laser technology can help extend the lifespan of engine components by preventing the buildup of harmful deposits. This can reduce the need for costly repairs and replacements in the future.

- Reduced maintenance: Laser cleaning is a quick and efficient process that requires minimal downtime for cleaning engine components. This can help reduce maintenance costs and improve overall productivity.

- Environmentally friendly: Laser cleaning does not produce any harmful byproducts or waste, making it a more sustainable cleaning solution for engine components.

Applications of laser cleaning in the automotive industry

Laser cleaning technology is widely used in the automotive industry for cleaning engine components, such as pistons, valves, and cylinder heads. It is also used for removing rust, paint, and other contaminants from metal surfaces.

Automotive manufacturers and repair shops can benefit from the use of laser cleaning technology to improve the performance and efficiency of their engines. By investing in laser cleaning equipment, they can ensure that their engine components are kept clean and well-maintained, leading to better overall performance and customer satisfaction.

Conclusion

Cleaning engine components with laser technology offers a precise and efficient solution for removing contaminants and improving performance. By investing in laser cleaning equipment, automotive manufacturers and repair shops can ensure that their engines operate at peak efficiency and longevity.

Laser cleaning of welding joints in automotive manufacturing

Welding joints play a crucial role in automotive manufacturing, as they are responsible for joining different components together to create a strong and durable structure. However, the welding process can leave behind unwanted residues such as spatter, oxides, and other contaminants that can affect the quality and integrity of the joint. To address this issue, laser cleaning has emerged as a highly effective and efficient method for cleaning welding joints in automotive manufacturing.

How does laser cleaning work?

Laser cleaning is a non-contact, environmentally friendly process that uses a high-intensity laser beam to remove contaminants from the surface of a material. The laser beam is focused on the welding joint, where it rapidly heats and vaporizes the contaminants, leaving behind a clean and smooth surface. This process is highly precise and selective, allowing for targeted cleaning without damaging the underlying material.

The benefits of laser cleaning

There are several benefits to using laser cleaning for welding joints in automotive manufacturing. Firstly, laser cleaning is a fast and efficient process that can be completed in a matter of seconds, making it ideal for high-volume production environments. Additionally, laser cleaning is a non-abrasive method that does not require the use of chemicals or abrasive materials, reducing the risk of damage to the material being cleaned. Furthermore, laser cleaning is a highly precise method that can be tailored to specific cleaning requirements, ensuring a high level of cleanliness and quality in the welding joint.

Applications of laser cleaning in automotive manufacturing

Laser cleaning is widely used in automotive manufacturing for cleaning welding joints in a variety of applications. For example, laser cleaning is commonly used in the production of car bodies, where welding joints are cleaned to ensure proper adhesion and strength. Additionally, laser cleaning is used in the manufacturing of exhaust systems, chassis components, and other critical automotive parts where clean welding joints are essential for performance and durability.

Challenges and considerations

While laser cleaning offers many benefits for cleaning welding joints in automotive manufacturing, there are also some challenges and considerations to keep in mind. For example, the cost of implementing laser cleaning technology can be high, requiring an initial investment in equipment and training. Additionally, the effectiveness of laser cleaning can be influenced by factors such as the type of material being cleaned, the thickness of the contaminants, and the power and intensity of the laser beam. It is important to carefully evaluate these factors and consider the specific requirements of the application before implementing laser cleaning in automotive manufacturing.

Conclusion

Laser cleaning is a highly effective and efficient method for cleaning welding joints in automotive manufacturing. By using a high-intensity laser beam to remove contaminants from the surface of a material, laser cleaning can ensure clean and smooth welding joints that meet the highest standards of quality and performance. While there are challenges and considerations to keep in mind, the benefits of laser cleaning make it a valuable tool for improving the cleanliness and integrity of welding joints in automotive manufacturing.

Application of laser cleaning in restoring vintage cars

Restoring vintage cars is a meticulous process that requires attention to detail and precision. One of the key technologies that has revolutionized the restoration process is laser cleaning. Laser cleaning is a non-contact, environmentally friendly method of removing rust, paint, and other contaminants from metal surfaces. In the context of restoring vintage cars, laser cleaning offers several advantages over traditional methods such as sandblasting or chemical stripping.

Advantages of Laser Cleaning

One of the main advantages of laser cleaning is its precision. The laser beam can be focused to a very small spot size, allowing for precise control over the cleaning process. This is particularly important when working on delicate vintage car parts that may be easily damaged by more aggressive cleaning methods. Additionally, laser cleaning is a non-abrasive process, meaning that it does not damage the underlying metal surface. This is crucial when working on valuable vintage cars that need to be preserved in their original condition.

Another advantage of laser cleaning is its efficiency. The process is much faster than traditional methods, allowing for quicker turnaround times on restoration projects. This is especially important for professional restoration shops that need to meet tight deadlines. Additionally, laser cleaning is a dry process, meaning that it does not produce any waste or harmful chemicals. This makes it an environmentally friendly option for restoring vintage cars.

Application of Laser Cleaning in Vintage Car Restoration

Laser cleaning can be used in a variety of ways in the restoration of vintage cars. One common application is the removal of rust from metal surfaces. Rust can be a major problem in vintage cars, causing structural damage and detracting from the overall appearance. Laser cleaning can effectively remove rust without damaging the underlying metal, allowing for a clean surface that can be primed and painted.

Another application of laser cleaning is the removal of old paint and coatings. Vintage cars often have multiple layers of paint that need to be removed before the car can be repainted. Laser cleaning can quickly and efficiently remove old paint without damaging the metal surface, saving time and effort in the restoration process.

Case Study: Laser Cleaning in Restoring a Vintage Car

Let’s take a look at a specific example of how laser cleaning was used in restoring a vintage car. A 1967 Ford Mustang was brought into a restoration shop with extensive rust and paint damage. The restoration team decided to use laser cleaning to remove the rust and old paint from the car’s body panels.

| Before Laser Cleaning |

After Laser Cleaning |

|

|

As you can see from the images above, the laser cleaning process was able to effectively remove the rust and old paint from the car’s body panels, revealing the original metal surface underneath. This allowed the restoration team to assess the extent of the damage and plan the next steps in the restoration process.

Conclusion

Laser cleaning is a valuable tool in the restoration of vintage cars, offering precision, efficiency, and environmental benefits. By using laser cleaning, restoration shops can quickly and effectively remove rust, paint, and other contaminants from metal surfaces without damaging the underlying material. This allows for a more efficient restoration process and helps to preserve the original condition of vintage cars for future generations to enjoy.

Benefits of laser cleaning for maintenance of automotive equipment

Laser cleaning is a cutting-edge technology that offers numerous benefits for the maintenance of automotive equipment. This innovative method uses a high-powered laser beam to remove contaminants, rust, paint, and other unwanted materials from surfaces without causing damage. In this article, we will explore the advantages of laser cleaning for automotive maintenance.

1. Precision Cleaning

Laser cleaning is a highly precise method that allows for targeted removal of contaminants from automotive equipment. The focused laser beam can be adjusted to remove only the unwanted material, leaving the underlying surface intact. This precision cleaning ensures that delicate components are not damaged during the maintenance process.

2. Non-contact Cleaning

Unlike traditional cleaning methods that involve abrasive materials or chemicals, laser cleaning is a non-contact process. This means that there is no physical contact between the cleaning tool and the surface being cleaned, reducing the risk of damage to the equipment. Non-contact cleaning also eliminates the need for harsh chemicals, making it an environmentally friendly option.

3. Cost-effective Maintenance

Laser cleaning offers a cost-effective solution for automotive maintenance. The efficiency and precision of this method reduce the need for manual labor and the use of expensive cleaning agents. Additionally, laser cleaning can be performed quickly, minimizing downtime and increasing productivity in the maintenance process.

4. Versatile Application

Laser cleaning can be used on a wide range of automotive equipment, including engine components, body panels, and wheels. This versatility makes it a valuable tool for maintaining various types of vehicles, from cars and trucks to motorcycles and ATVs. Whether removing rust from metal surfaces or cleaning paint from plastic parts, laser cleaning can handle a variety of maintenance tasks.

5. Improved Safety

Traditional cleaning methods often involve the use of hazardous chemicals or abrasive materials that can pose risks to workers and the environment. Laser cleaning eliminates these safety concerns by using a clean and efficient process that does not produce harmful fumes or waste. This makes it a safer option for automotive maintenance professionals and reduces the impact on the environment.

6. Enhanced Durability

By removing contaminants and rust from automotive equipment, laser cleaning helps to improve the durability and longevity of the components. Clean surfaces are less prone to corrosion and wear, resulting in equipment that performs better and lasts longer. This can lead to cost savings in the long run by reducing the need for frequent repairs or replacements.

7. Time-saving Solution

One of the key benefits of laser cleaning for automotive maintenance is its time-saving nature. The efficiency and precision of this method allow for quick and thorough cleaning of equipment, reducing the time required for maintenance tasks. This can help automotive professionals to complete jobs faster and more efficiently, improving overall productivity in the workshop.

Conclusion

Overall, laser cleaning offers numerous benefits for the maintenance of automotive equipment. From precision cleaning and cost-effectiveness to improved safety and durability, this innovative method provides a versatile and efficient solution for keeping vehicles in top condition. By incorporating laser cleaning into their maintenance routines, automotive professionals can enjoy a range of advantages that contribute to better performance and longevity of their equipment.

Nazywam się Piotr Kulik i jestem specjalistą SEO, Google Ads i Analytics. Posiadam certyfikaty Google z zakresu reklamy i analityki oraz doświadczenie w pozycjonowaniu stron oraz sklepów internetowych.

Jeśli interesują Cię tanie sponsorowane publikacje SEO bez pośredników - skontaktuj się z nami:

Tel. 511 005 551

Email: biuro@codeengineers.com