Introduction to laser cleaning technology

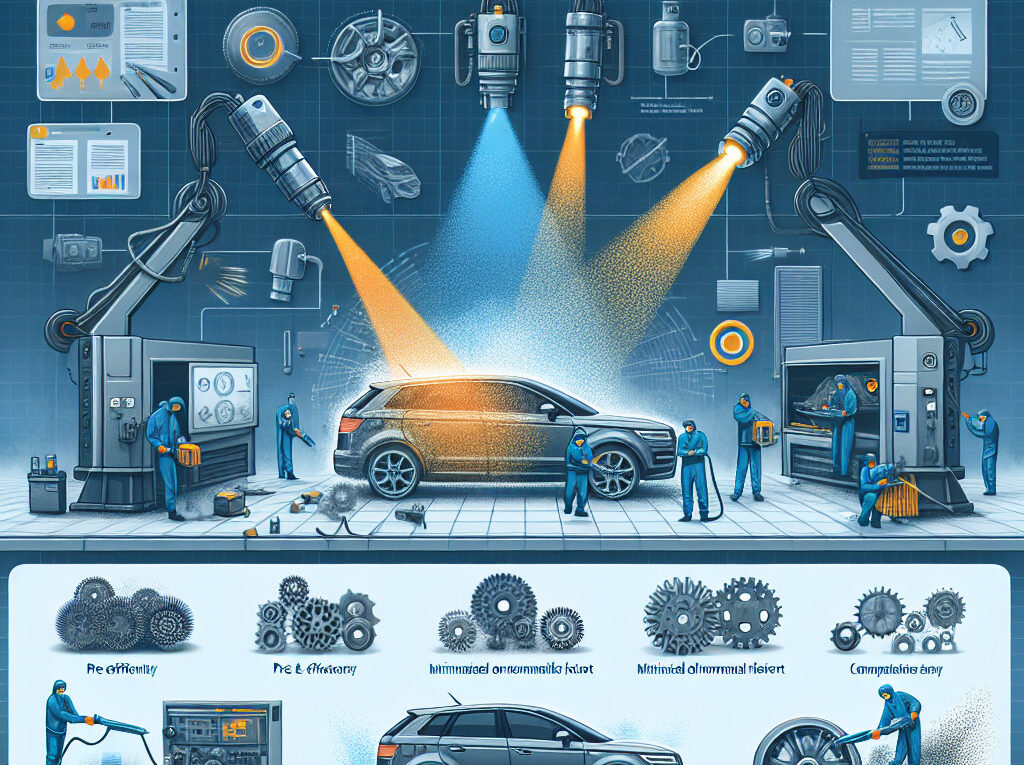

Laser cleaning technology is a cutting-edge method used to remove contaminants, coatings, rust, and other unwanted materials from surfaces. This innovative technique utilizes the power of laser beams to vaporize or ablate the unwanted substances, leaving behind a clean and pristine surface. Laser cleaning technology offers numerous advantages over traditional cleaning methods, including precision, efficiency, and environmental friendliness.

How does laser cleaning technology work?

Laser cleaning technology works by focusing a high-intensity laser beam onto the surface to be cleaned. The energy from the laser beam interacts with the contaminants on the surface, causing them to either vaporize or ablate. The process is highly precise, allowing for selective removal of specific materials without damaging the underlying surface. Laser cleaning technology can be used on a wide range of materials, including metals, plastics, ceramics, and composites.

Advantages of laser cleaning technology

– Precision: Laser cleaning technology allows for precise control over the cleaning process, ensuring that only the unwanted materials are removed without damaging the surface.

– Efficiency: Laser cleaning technology is a fast and efficient method of cleaning surfaces, reducing the time and labor required compared to traditional methods.

– Environmental friendliness: Laser cleaning technology is a non-contact and chemical-free method of cleaning, making it environmentally friendly and safe for use in a variety of applications.

🔹Key features of laser cleaning technology🔹

– Non-contact cleaning method

– Selective removal of contaminants

– Minimal heat-affected zone

– No damage to the underlying surface

– Environmentally friendly

🌟Laser cleaning technology is revolutionizing the way surfaces are cleaned and prepared for further processing. With its precision, efficiency, and environmental friendliness, laser cleaning technology is becoming the method of choice for industries ranging from automotive to aerospace. As technology continues to advance, laser cleaning technology is expected to play an even greater role in surface cleaning and preparation.

#laser #cleaning #technology

Long-tail phrases:

– Laser cleaning technology for industrial applications

– Benefits of laser cleaning technology in aerospace industry

– How laser cleaning technology is changing the automotive industry landscape

Traditional methods of cleaning boat hulls

- Scraping 🛠️: One of the oldest methods of hull cleaning involves physically scraping off marine growth using a scraper or putty knife. This method is effective but can be time-consuming and labor-intensive.

- Pressure washing 💦: Using a high-pressure water jet to remove marine growth from the hull is a quick and efficient method. However, care must be taken not to damage the hull or paint with excessive pressure.

- Chemical cleaners 🧪: There are a variety of chemical cleaners available that can dissolve and remove marine growth from the hull. These cleaners are often applied and left to sit for a period of time before being rinsed off.

- Biocide coatings 🦠: Some boat owners choose to apply biocide coatings to their hulls to prevent marine growth from attaching in the first place. These coatings release chemicals that inhibit the growth of organisms.

- Diving 🏊♂️: For boats that are kept in the water year-round, hiring a diver to periodically clean the hull can be an effective method. Divers can physically remove marine growth and inspect the hull for any damage.

Overall, keeping your boat hull clean is essential for maintaining its performance and longevity. By using traditional cleaning methods such as scraping, pressure washing, chemical cleaners, biocide coatings, and diving, you can ensure that your vessel stays in top condition for years to come.

#boatmaintenance, #hullcleaning, #marinegrowth, #traditionalmethods

frazy kluczowe:

– How to clean boat hulls effectively

– Best practices for hull maintenance

– Preventing marine growth on boat hulls

Advantages of laser cleaning for removing algae and barnacles

Advantages of laser cleaning:

| Advantage |

Description |

| 1. Precision |

Laser cleaning allows for precise targeting of algae and barnacles without damaging the underlying surface. |

| 2. Efficiency |

Laser cleaning is a fast and efficient method of removing algae and barnacles, saving time and labor costs. |

| 3. Environmentally friendly |

Laser cleaning does not require the use of harsh chemicals, making it a more eco-friendly option. |

| 4. Non-contact |

Laser cleaning is a non-contact method, reducing the risk of damage to the surface being cleaned. |

Overall, laser cleaning offers a number of advantages for removing algae and barnacles from marine structures. It is a precise, efficient, environmentally friendly, and non-contact method that can help maintain the integrity and efficiency of vessels and other marine structures.

#laser #cleaning #algae #barnacles #marine #environment #efficiency

Keywords: laser cleaning, algae removal, barnacle removal, marine structures, efficiency, environmentally friendly

Long-tail phrases: advantages of laser cleaning for removing algae and barnacles, precision of laser cleaning, efficiency of laser cleaning, environmentally friendly algae removal, non-contact barnacle removal.

Challenges and limitations of laser cleaning for boat hulls

Challenges:

- Effectiveness on different materials: Laser cleaning may not be as effective on certain materials, such as fiberglass, as it is on metals.

- Cost: The initial investment in laser cleaning equipment can be high, making it a less accessible option for some boat owners.

- Safety concerns: Laser cleaning requires proper training and safety precautions to prevent accidents and injuries.

- Regulations: Some areas may have restrictions on the use of lasers for cleaning boat hulls, making it difficult to use this method in certain locations.

Limitations:

- Depth of cleaning: Laser cleaning may not be able to remove all layers of marine growth or paint, leaving some residue behind.

- Surface damage: If not used properly, lasers can cause damage to the boat hull, leading to costly repairs.

- Speed: Laser cleaning can be a slower process compared to other methods, which may not be ideal for boat owners looking for quick results.

Despite these challenges and limitations, laser cleaning remains a promising option for boat hull maintenance. With proper training and equipment, boat owners can effectively use lasers to keep their vessels clean and well-maintained.

#laser #cleaning #boat #hulls

, laser cleaning equipment, marine growth, boat hull maintenance, environmental friendliness, safety concerns, surface damage, regulations, cost, effectiveness, speed, fiberglass, paint, restrictions, training, accidents, injuries.

The potential for using laser cleaning technology for cleaning oil spills

Laser cleaning technology works by using high-powered lasers to vaporize contaminants, such as oil, without damaging the underlying surface. This process is known as laser ablation, and it has been used successfully in a variety of industrial applications, including cleaning metal surfaces and removing paint. lies in its ability to quickly and effectively remove oil from a variety of surfaces, including rocks, sand, and even water.

One of the key advantages of using laser cleaning technology for cleaning oil spills is its precision. Unlike traditional methods, which can be messy and imprecise, laser cleaning technology can target specific areas of contamination with pinpoint accuracy. This means that clean-up crews can remove oil from sensitive habitats, such as coral reefs or mangrove forests, without causing further damage. Additionally, laser cleaning technology is non-contact, which means that it can be used safely in hazardous or hard-to-reach areas.

Another advantage of using laser cleaning technology for cleaning oil spills is its speed. Traditional clean-up methods can be time-consuming and labor-intensive, requiring large crews and heavy equipment. In contrast, laser cleaning technology can remove oil quickly and efficiently, reducing the time and cost associated with clean-up efforts. This can be especially important in the event of a large-scale oil spill, where rapid response is critical to minimizing environmental damage.

Despite these advantages, there are still some challenges to using laser cleaning technology for cleaning oil spills. One of the main challenges is the cost of the technology, which can be prohibitively expensive for some clean-up operations. Additionally, laser cleaning technology requires specialized training and equipment, which may not be readily available in all regions. However, as the technology continues to advance and become more widely adopted, these challenges are likely to become less significant.

In conclusion, is significant. With its precision, speed, and efficiency, laser cleaning technology has the potential to revolutionize the way we clean up oil spills and protect our environment. By investing in research and development, and by training clean-up crews in the use of this technology, we can harness the power of lasers to create a cleaner, safer world for future generations.

#oilspills #environment #cleaningtechnology #laserablation #precisioncleaning

frazy kluczowe:

– potential for using laser cleaning technology for oil spill clean-up

– advantages of laser cleaning technology for environmental clean-up efforts

– challenges of using laser cleaning technology for oil spill remediation

– future prospects for laser cleaning technology in environmental protection efforts

The impact of biofouling on marine industries such as shipping and aquaculture

One of the main concerns with biofouling is its impact on the efficiency of ships. When organisms attach themselves to the hull of a ship, they create drag, which can increase fuel consumption and reduce speed. This not only increases operating costs for shipping companies but also contributes to greenhouse gas emissions.

In aquaculture, biofouling can pose a threat to the health of farmed fish and shellfish. Fouling organisms can compete with farmed species for food and space, leading to reduced growth rates and lower yields. In addition, biofouling can introduce pathogens and parasites to aquaculture facilities, increasing the risk of disease outbreaks.

Efforts to control biofouling in marine industries have traditionally involved the use of antifouling coatings. These coatings release toxic substances that deter fouling organisms from attaching to surfaces. However, the use of these coatings has raised environmental concerns due to the release of harmful chemicals into the marine environment.

As a result, there is growing interest in developing alternative methods for biofouling control. One promising approach is the use of biofouling-resistant materials, such as silicone-based coatings that prevent organisms from attaching to surfaces. Other strategies include the use of ultrasonic or electric currents to deter fouling organisms.

Overall, the impact of biofouling on marine industries such as shipping and aquaculture is significant and multifaceted. It affects the efficiency and profitability of businesses, as well as the health and sustainability of marine ecosystems. Finding sustainable solutions to biofouling is crucial for the long-term viability of these industries.

- shipping

- aquaculture

- biofouling

- antifouling coatings

- marine ecosystems

- impact of biofouling on marine industries

- efficiency of ships

- aquaculture

- antifouling coatings

- sustainable solutions

#shipping #aquaculture #biofouling #antifoulingcoatings #marineecosystems

Safety considerations when using laser cleaning technology

Laser cleaning technology is a powerful tool that can effectively remove rust, paint, and other contaminants from various surfaces. However, it is important to consider safety precautions when using this technology to prevent accidents and injuries. Here are some safety considerations to keep in mind:

1. Protective gear: When using laser cleaning technology, it is essential to wear appropriate protective gear, such as safety goggles, gloves, and a face shield. This will help protect your eyes, skin, and respiratory system from potential hazards.

2. Training: Before using laser cleaning technology, it is important to undergo proper training to understand how to operate the equipment safely. This includes learning how to adjust the laser settings, handle the equipment properly, and troubleshoot any issues that may arise.

3. Environmental considerations: When using laser cleaning technology, it is important to consider the environment in which you are working. Make sure the area is well-ventilated to prevent the buildup of fumes and dust. Additionally, be mindful of any flammable materials that may be present and take precautions to prevent fires.

4. Distance: It is important to maintain a safe distance from the laser cleaning equipment while it is in operation. This will help prevent accidental exposure to the laser beam, which can cause burns and other injuries.

5. Regular maintenance: To ensure the safe operation of laser cleaning technology, it is important to perform regular maintenance on the equipment. This includes checking for any signs of wear and tear, replacing worn parts, and calibrating the laser settings as needed.

By following these safety considerations, you can help prevent accidents and injuries when using laser cleaning technology. Remember to always prioritize safety and take the necessary precautions to protect yourself and others in the work environment.

#safety #laser #cleaning #technology #protectivegear #training #environmentalconsiderations #distance #regularmaintenance

słowa kluczowe: safety, laser cleaning, technology, protective gear, training, environmental considerations, distance, regular maintenance

frazy kluczowe: laser cleaning technology safety precautions, laser cleaning equipment operation, laser cleaning technology environmental safety, laser cleaning technology maintenance, laser cleaning technology safety measures.

The future of laser cleaning technology in marine industry

Advantages of laser cleaning technology

One of the main advantages of laser cleaning technology is its precision. Laser beams can be focused on specific areas, allowing for targeted cleaning without damaging surrounding surfaces. This level of precision is particularly important in the marine industry, where delicate equipment and surfaces need to be cleaned without causing any damage.

Another advantage of laser cleaning technology is its efficiency. Laser beams can remove contaminants quickly and effectively, reducing the time and labor required for cleaning. This can lead to cost savings for marine companies and increased productivity.

The future of laser cleaning technology in the marine industry

As technology continues to advance, the future of laser cleaning technology in the marine industry looks promising. Researchers and engineers are constantly working to improve the efficiency and effectiveness of laser cleaning systems, making them even more suitable for marine applications.

One area of focus for future development is the power and speed of laser cleaning systems. By increasing the power and speed of laser beams, cleaning processes can be completed more quickly and effectively. This will allow marine companies to clean surfaces more efficiently and reduce downtime.

Another area of development is the portability of laser cleaning systems. As technology becomes more compact and lightweight, laser cleaning systems can be easily transported to different locations, making them more versatile and convenient for marine companies.

Conclusion

The future of laser cleaning technology in the marine industry is bright. With its precision, efficiency, and potential for future development, laser cleaning technology is set to revolutionize the way surfaces are cleaned in the marine industry. As researchers and engineers continue to innovate and improve laser cleaning systems, we can expect to see even greater adoption of this technology in the years to come.

#laser #cleaning #technology #marine #industry

słowa kluczowe: laser, cleaning, technology, marine, industry

frazy kluczowe: laser cleaning technology in marine industry, future of laser cleaning technology, precision of laser cleaning, efficiency of laser cleaning, portability of laser cleaning systems.

Nazywam się Łukasz Woźniakiewicz, jestem właścicielem i CEO w Codeengineers.com, agencji marketingu internetowego oferującej między innymi takie usługi jak pozycjonowanie stron/sklepów internetowych, kampanie reklamowe Google Ads.

Jeśli interesują Cię tanie sponsorowane publikacje SEO bez pośredników - skontaktuj się z nami:

Tel. 505 008 289

Email: ceo@codeengineers.com